Water injection is the most effective anti-knock device you can install on your car, this allows boost and timing levels normally requiring expensive race gas, but with pump gasoline. As an example with 93 octane (R+M)/2 and water injection, the effective octane of the mixture can be as high as 116 octane and that's with water alone, adding methanol to the mix can make it even higher.

1. This system has a number of advantages over others on the market.

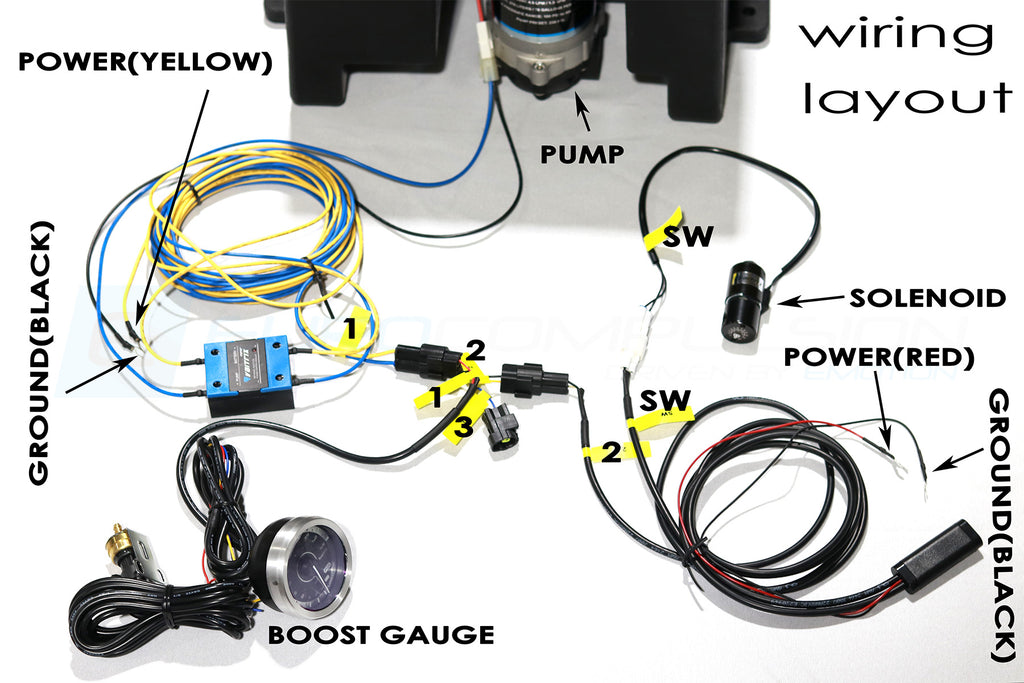

First of all, it's controlled by a microprocessor in the included boost gauge and it's programmed with a little remote control right through that gauge. No need to get out a laptop or figure out how to mount some cumbersome controller and its wiring. Programming is easy too. Simply select the boost level at which you want the spray to start and the boost level at which you want maximum spray. The controller will then start at your selected point and increase the spray quantity at the higher boost setting.

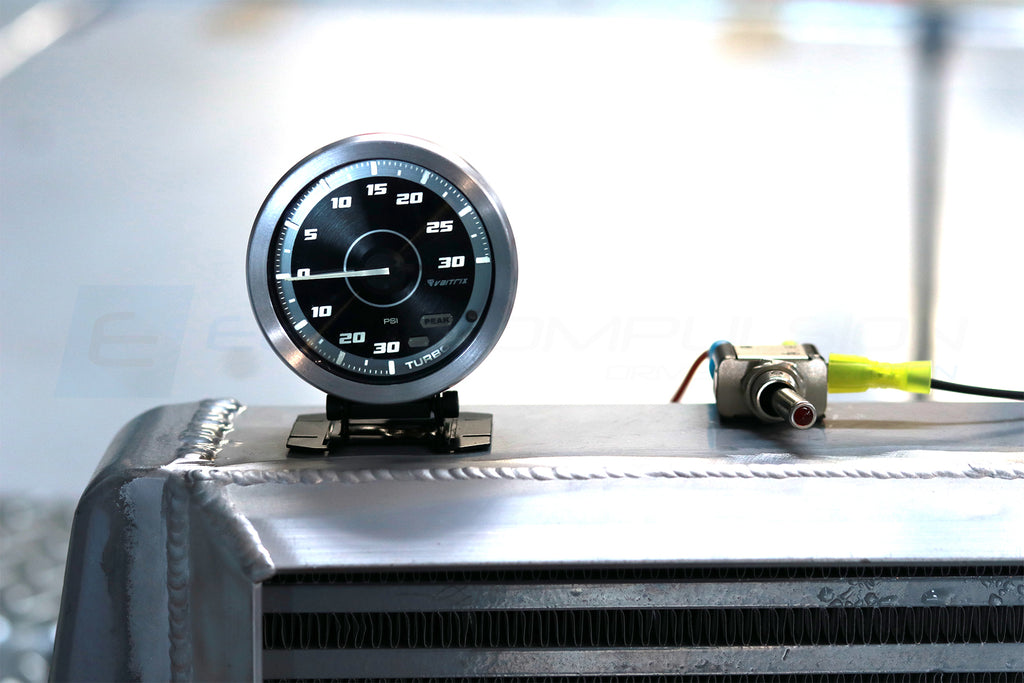

This is also a very good boost gauge with a lot of features. It's very accurate, has a tattle-tale high boost recall, an adjustable overboost warning which is loud, adjustable bright and dim feature along with an automatic mode for this. Everyone in our shop uses the automatic bright/dim and it works perfectly.

2. The tank holds 3 gallons, that's a lot. It's a quality tank that's made to ensure water will feed to the pump under hard acceleration even when the tank is at relatively low fluid levels. The tank is made to look like a subwoofer so you can maintain a low profile if operating in areas where that's desirable.

3. All other components in the kit are first-rate, The connections are secure, won't leak if assembled correctly, and are all methanol compatible.

INCLUDED COMPONENTS:

- Boost Gauge/Controller

- Remote Controller/Programmer

- Wiring Harnesses

- Nozzle with Nozzle Holder

- Solenoid with associated wiring

- Pump 400psi capable, factory set to 260psi (which is where our nozzle flow rates are measured)

- Power Supply/Pump Controller

- Tank 3 gallon capacity

- Tubing 19 feet

- All needed connectors

Note: Nozzle size is highly dependent on specific engine details. As a very General rule select a nozzle size that flows water at about 1/3 the rate at which the engine uses fuel. For example a typical 100 horsepower engine will use 50 pounds of fuel. Water is about 8 pounds per gallon so that works out to just over 2 gallons per hour or 126cc/min. Keep in mind you can adjust the flow rates down with the controller and up or down via the pump adjustment if needed.