This is Part 3 of my series on the 4C's engine. If you haven't already read them, please read Parts 1 and 2.

As I explained in the previous 2 parts of this series, the 4C's engine is specifically designed to take advantage of turbocharging, so it makes sense to take some time to understand the turbocharging system.

A turbocharger is an exhaust driven compressor that forces more air into the engine than it would be able to ingest on it's own. Exhaust exits the engine and flows through the exhaust manifold. From there is passes through the turbine, which in turn spins the compressor and boosts the air pressure. Since higher air pressure with other factors equal means more air molecules in the intake manifold, which then ends up in the combustion chamber we can burn more fuel and make more power with turbo boost.

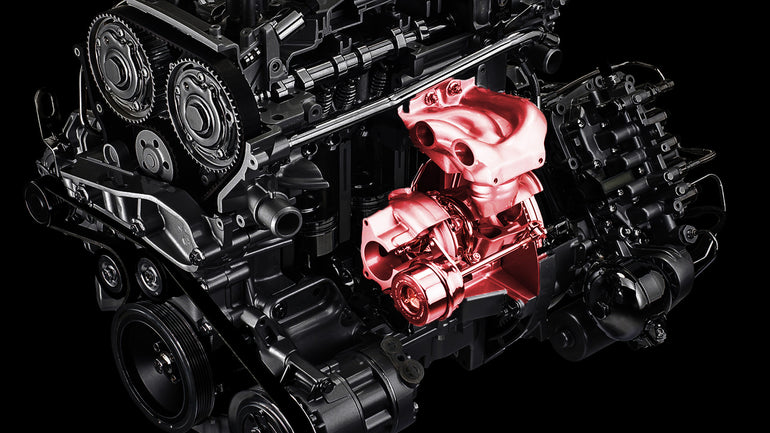

Let's look at a cutaway picture of a turbo:

The red section is the turbine housing, where the exhaust passes through the turbine to spin the whole unit. The blue section is the compressor section. This isn't a 4C turbo, but it's functionally similar.

In the center section of the turbo we have a shaft. The shaft is oiled by pressurized engine oil going in at the top of the turbo, and then it drains back into the engine and returns to the oil pan.

The speed of the turbo is regulated by a wastegate that opens to allow exhaust to bypass the turbo, thus slowing it down, or vice-verse. The wastegate is pneumatically actuated and electronically controlled. That means the ECU decides where to position the wastegate based on the desired boost level and then uses air pressure to move it.

So we can start to put all this together, let's go over a full throttle blast from idle up to redline and talk about what happens in the 4C.

When you apply full throttle from idle, there won't be enough exhaust flow to get the turbo spinning fast enough to create any boost. The engine is essentially normally aspirated until it reaches it's boost threshold, which is the engine rpm at which there is enough exhaust flow to generate boost.

As the engine rpm rises the turbo speeds up and creates boost. The ECU will monitor pressure on both sides of the throttle, and temperature after the throttle. It will typically adjust the wastegate to maintain about 20 pounds of boost. It can go as high a 21.75 under some conditions (I am talking about stock boost levels right now) but will normally peak around 20psi. The ECU has some complex tables to decide on the actual amount of boost to be used. At higher RPM it will reduce boost until redline when the transmission shifts gears.

At coming out of the turbo is hot. Just how hot depends on how much is been pressurized and the efficiency of the turbo at that moment. When the air is on it's way to the intake manifold, it passes through an intercooler where it cools off before heading into the engine.

Now when the throttle closes an interesting thing happens. If nothing happens to prevent it, boost pressure will spike in the intercooler piping, and it will spike up as high at 100PSI. Now this 100psi can't hurt the engine, because the throttle is closed, but it can damage the intercooler piping and even the turbocharger itself. So, when the throttle closes there is a pressure relief system called a “Dump Valve” this valve is on the compressor housing of the turbo and routes the boosted air back into the intake side of the compressor. The valve is controlled by the ECU. In addition to normal Dump valve operation The ECU can open this valve in the event of various malfunctions in order to cut boost.

As seen in this picture, the dump valve on the turbo is tied into a solenoid valve, the vacuum pump, and the intake manifold.

So boost is controlled by the ECU which regulates it primarily through positioning of the wastegate to force exhaust to go through the turbo, or allow some of it to pass around the turbo. The wastegate is actually located in the turbo's internals. The ECU can also regulate boost to an extent via the dump valve. If these things don't work, the ECU will close the throttle to protect the engine. So, the ECU has a huge amount of authority over boost.

Here is the entire system:

Occasionally when you shut the engine off, you may hear a small electric pump running. That's the turbocharger cooling electric pump. It's job is to cool the turbo after you have shut off the engine.

This pump does not circulate oil. So as soon as you shut off the engine, oil pressure to the pump drops to zero. This won't hurt anything as long as the turbo isn't spinning really fast when the oil pressure drops. I suggest making a habit of always driving off boost and at light throttle for the last minute before parking. This will extend the turbo bearing life practically to infinity, provided all your maintenance is up to par.

Back to the electric pump. It's controlled by the ECU. The ECU looks at various factors and then decides to either turn the pump on or leave it off. The key factors are coolant temp, intake air temp, running time, and gasoline temperature. If it decides to run the pump it will leave it on for about 10 mins. The pump is located under the expansion tank and is switched on through a relay.

The 4C's turbo and limitations:

All turbos have limitations of one kind or another. For example smaller turbos can spin up quickly lowering the boost threshold and reducing lag. However they can't generate as much total airflow, and thus power as relatively larger turbos (it should go without saying, but this is will all other factors equal).

Turbochargers have three main limitations, all three of which are inter related. They are turbine speed, boost, and efficiency. There has been a lot of talk about these limitations, but until now, nobody in the Alfa community has put up any facts about them. We hear a lot of statements like “the turbo is only good for 2XX horsepower” or something similar but nothing to back that up.

The important thing to understand is that turbos don't really have a specific limitation for horsepower. They do have airflow limitations, but what that really means is that the turbo becomes less and less efficient as if flows more and more air, at at a certain point, it makes sense to select a bigger turbo. It does not mean that you can't run the turbo up to higher airflow numbers.

Let's look at a Garrett compressor map and go over some terms. (picture is NOT the 4C's turbo)

Now this picture is very helpful in understanding turbo limitations. The main limit is the “Choke Line”. You generally don't want to go to the right of that. Air flow directly relates to horsepower, you can generally ESTIMATE about 10 horsepower for each lb/min of airflow. So this turbo will reach the choke line at about 475 horsepower. Of course that's at a pressure ratio of 2.5:1, which is about 22 pounds of boost.

Does this mean that you CAN'T go past the choke line. NO it does not. Garrett says this: “The Choke Line is the right hand boundary of the compressor map. For Garrett maps, the choke line is typically defined by the point where the efficiency drops below 58%.“ There are other limitations to keep in mind, but that's usually the first one you run into.

Of course our beloved 4C uses a Borg Warner turbocharger. Borg Warner used compressor maps just like Garrett's.

Let's look at a typical Borg Warner Turbo, not the 4C's but another one.

That's a huge range of acceptable horsepower. Now if you were specifically building a 450 horsepower engine, you probably wouldn't select this turbo, because that's in the upper range of what it can do, but if you had a 240hp engine and wanted 300, you probably wouldn't swap out this unit.

Let's look at Borg Warner's compressor map for the turbo I just showed you:

It's apparent here that Borg Warner is basing that 450hp number off of it's max airflow at about 44 lbs/min, that makes sense. This specific turbo is also at it's shaft speed limit at that point of 167,900rpm. It's adiabatic efficiency will be down around 60% under those conditions, so it makes sense that you would want a bigger turbo if you needed to go beyond those numbers.

So....what about the 4C's turbo?

There has been a lot of saber rattling in this area, but very few facts. I am going to try and fix that.

The turbo has two “limitations” published in official Alfa manuals. The first is a max pressure limit of 1.5 bar (21.75 psi). That is NOT a maximum limit for the turbo. It's actually the maximum amount that the turbo should ever generate with the stock tune. Those are two very different things. As we will see, the turbo can go a lot higher.

The second published limit is a temperature limit of 980C (sometimes 1020C). that is an actual number that shouldn't be exceeded, but 980C is really, really hot and that gives us a lot of room to work with when tuning.

The Alfa 4C uses the Borg Warner K04 2280 DCBCB 688 turbocharger. That's an Alfa Specific turbo, that's welded to the exhaust manifold. Alfa has never published the compressor map for this turbo, neither has Borg Warner. However, the same basic turbo is available in various configurations. Some are made to bolt to an exhaust manifold, some are oriented in different ways.

We can look at a compressor map for a more generic K04 2280, which will give very similar numbers, so let's do that.

First, let's look at the maximum boost this turbo can provide according the the chart. It peaks at a pressure ratio of about 3.2:1 but only in a very limited range. It's real useful max is about 3:1 which it can maintain over a very wide range of airflow. That works out to a maximum boost of 29.4psi. Guess what the maximum boost is that the 4C's two boost sensors can read? It's 29.4psi. Coincidence? I think not.

What about airflow. Well, this chart gives those numbers in cubic meters per second. That's not the industry standard of lbs/min, but we can convert it. POINT 1 (.1) on the chart is equal to about 16.14 lbs/min or enough for an easy 160 horsepower. The chart goes all the way to .234. That's in no way an absolute limitation, but let's do the math anyway. That's 37.76 pounds per hour. Now that's only at a very specific point on the chart so let's look at more realistic number. It can maintain anything from 14 pounds of boost all the way up to 29.4 while staying at an adiabatic efficiency number of around 70% and it can do it at .21 cubic meters per second. That 33.984 lbs/min is enough for an easy 340 horsepower.

I am sure some naysayers will point out rounding errors, or the fact that this isn't the exact Borg Warner chart for the 4C. However it's the closest chart we have, and I think I explained the logic of why these are not hard limits anyway. The Alfa's stock turbo is a lot better than some people think. (note: since this article first appeared, the naysayers have changed their story and are now claiming that it's not the compressor that's the limitation, it's some other aspect of the turbo. This is pure nonsense. Borg Warner isn't going to supply and OEM turbo with a compressor that doesn't match the rest of the capabilities of the turbo and if anyone says they have evidence showing otherwise, ask to see it!)

Our most aggressive tune at the time of this writing has approx. 320whp. That's nominally about 35hp more than our major competitor who has said we are above the limits of the turbo. Think this over, our numbers are WITH a specific free flowing intake and Novitec's excellent exhaust. These measurements are also taken on the road so we have 80mph of air blasting through the intercooler and pressuring the air inlet, not heat soaked on a rolling road dyno with a fan blowing on the front of the car. Our numbers are also totally within the confines of the closest known compressor map.

I am not saying that there isn't room for improvement with a bigger turbo. It should be obvious that if we can get the airflow and boost but move the efficiency to 75% that may be worth doing, and it can be done with a bigger turbo, so nothing I say here should be construed as saying that I am against bigger turbos, I am not. What I am stating, is that the factory turbocharger Alfa Romeo used is good for power levels higher than what most people would think, and has quite a bit of room for power left on the table.